หมวดหมู่สินค้า

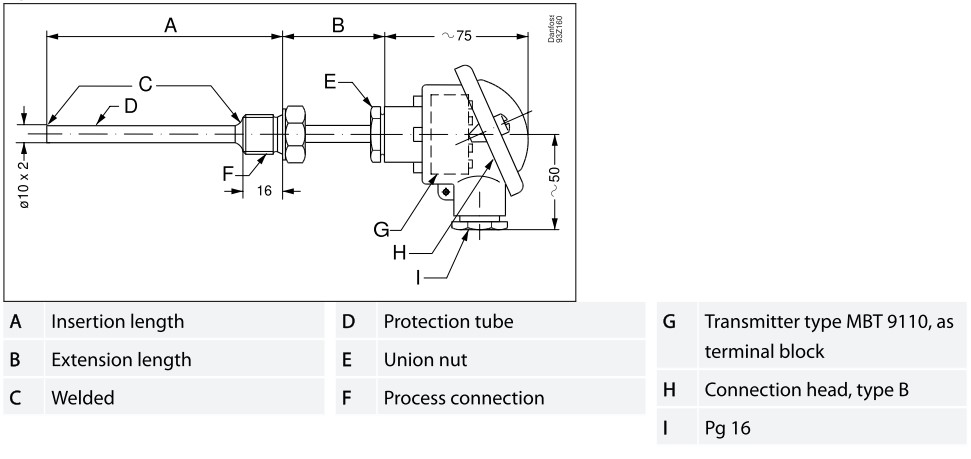

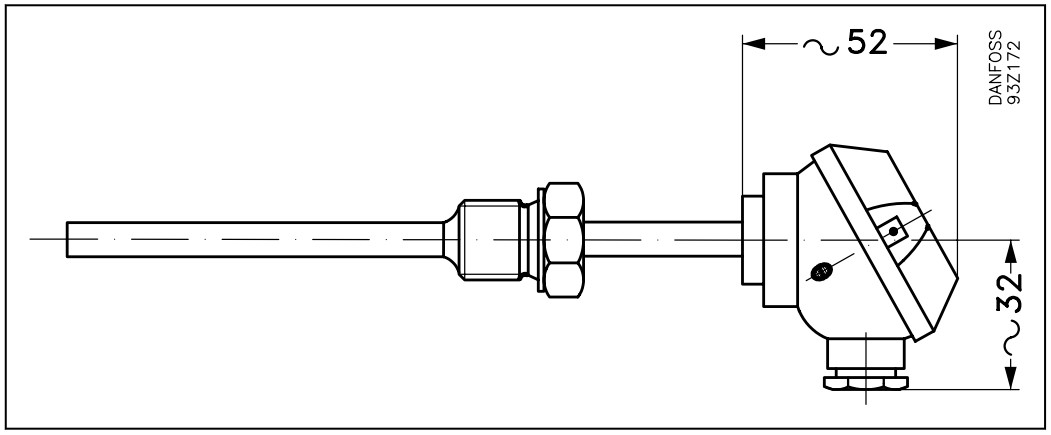

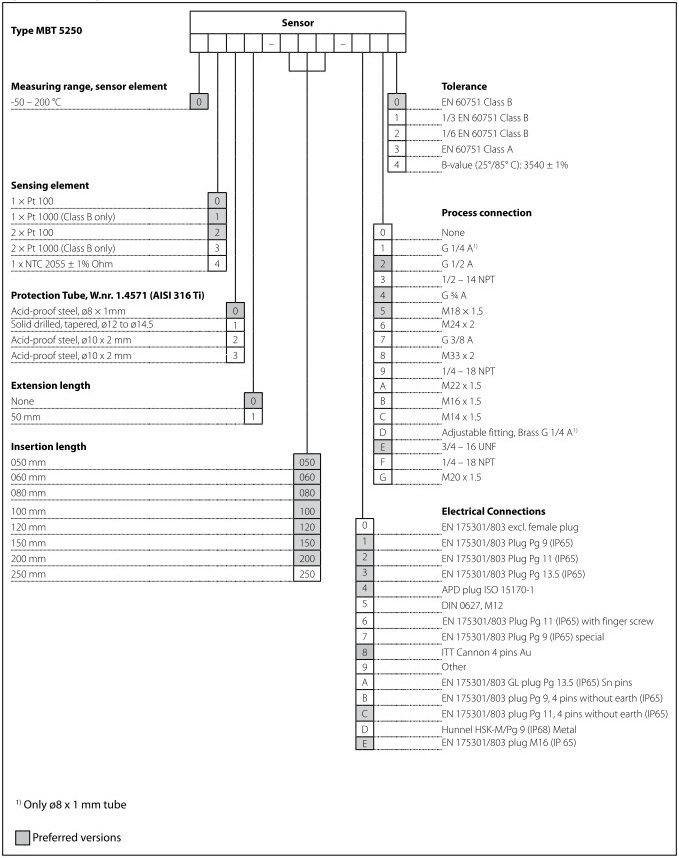

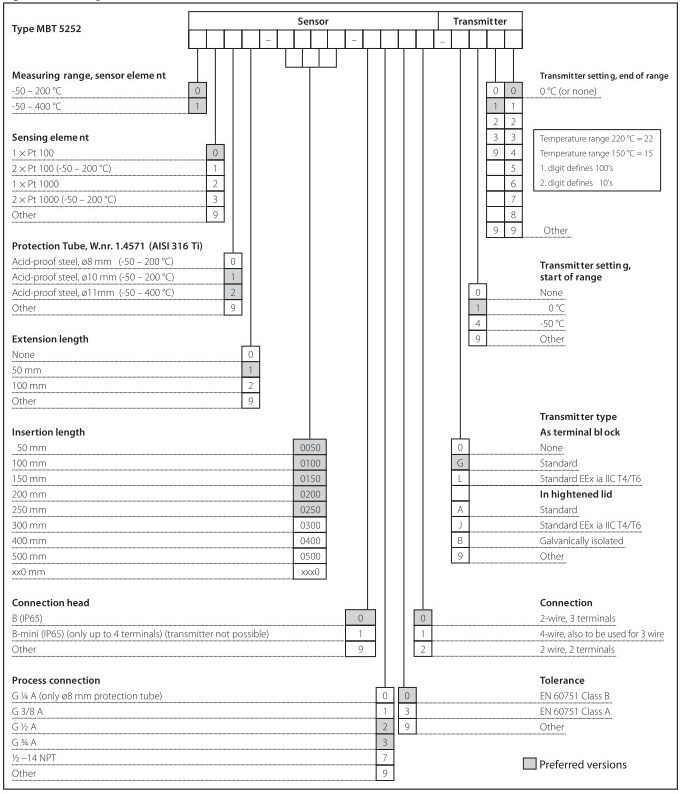

DANFOSS MBT 5250/5252 Series is an industrial temperature sensor range designed for refrigeration systems, marine applications, and fluid-handling processes in industrial plants. It delivers accurate temperature measurement in media such as water, oil, and gases.

With a wide operating temperature range, the MBT 5250/5252 Series supports Pt100 / Pt1000 sensing elements, offers strong vibration resistance, and can be specified with an integrated 4–20 mA transmitter for seamless use in automated control systems.

DANFOSS MBT 5250/5252 Series is built for industrial-duty temperature measurement in refrigeration, marine systems, and factory processes where liquids and gases must be monitored reliably. The design emphasizes accuracy, durability, and stable long-term performance.

These sensors are suitable for a broad range of media, including water, lubricating oil, hydraulic oil, air, steam, and industrial gases. You can select either a Pt100 or Pt1000 sensing element to match the requirements of your control system.

The sensing stem is made from high-grade stainless steel, and the silicone cable improves resilience in vibrating environments. The series supports operating temperatures from -50°C to 200°C, and up to 400°C in certain versions.

| Features | Description | |

| Measuring range | -50 – 200 °C | |

| Sensing element | Pt 100, Pt 1000 | |

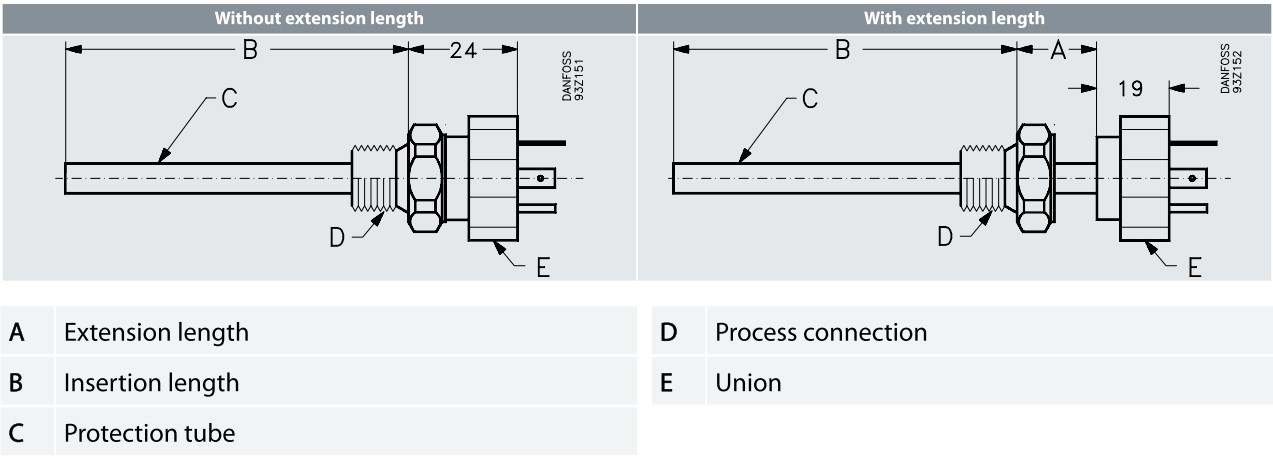

| Protection tube | ø8 × 1 mm | |

| Permissible media velocity | Air | 25 m/s |

| Water | 3 m/s | |

| Process connection | G ¼ A | G ¼ A | G ¾ A M24 |

| G ³⁄₈ A – M18 | |||

| Max. tightening torque | 25 Nm | 50 Nm | 100 Nm |

| Features | Description | |

| Sensor tolerances | EN 60751 Class B: ± (0.3 + 0.005 × t) | t = temperature of medium, numerical value |

| Shock: | 100 g / 6 ms | |

| Vibration stability | Vibrations: | 4 g sine function 5 – 200 Hz, measured acc. to IEC 60068-2-6 |

| Enclosure | IP65 according to IEC 60529 | |

| Cable entry EN 175301-803 | Pg 9, Pg 11 or Pg 13.5 | |

| Features | Description |

| Protection tube in contact with media | W.no. 1.4571 (AISI 316 Ti) |

| Process connection | W.no. 1.4404 (AISI 316 L) |

| Extension length | W.no. 1.4571 (AISI 316 Ti) |

| Union | Nickel plated brass |

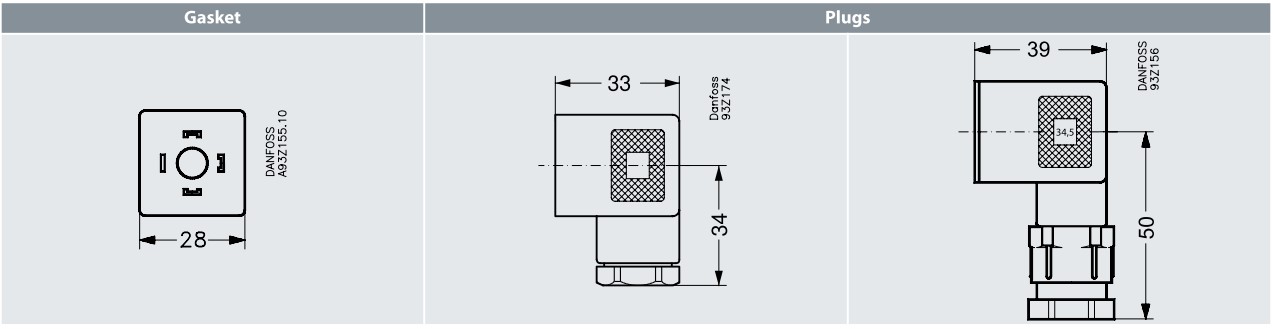

| Gasket | Silicone |

| Plug EN 175301-803 | PA 6.6 (max 125 °C) |

| Features | Description | |

| Measuring range | -50 – 200 °C or -50 – 400 °C | |

| Sensing element | Pt 100, Pt 1000 | |

| Protection tube | Low temperature: ø10 × 2 mm High temperature: ø11 × 1 mm | |

| Permissible media velocity | Air | 25 m/s |

| Stream | 25 m/s | |

| Water | 3 m/s | |

| Process connection | G ¼ | G ¼ A – G ½ A | G ¾ A M24 |

| G ³⁄₈ A – M18 | |||

| Max. tightening torque | 25 Nm | 50 Nm | 100 Nm |

| Features | Description | |

| Max. ambient temperature(1) | Sensors without transmitter | 90 °C |

| Sensors with transmitter | 85 °C | |

| Sensor tolerance | EN 60751 Class B: ± (0.3 + 0.005 × t) | t = temperature of medium, numerical value |

| Shock: | 100 g / 6 ms | |

| Vibration stability | Vibrations: | 4 g sine function 5 – 200 Hz, measured acc. to IEC 60068-2-6 |

| Enclosure | IP65 according to IEC 60529 | |

| Cable entry B-head | Pg16 | |

| Cable entry BM | Pg 9 | |

| Temperature transmitter MBT 9110 | Supply voltage: | 8 – 35 V DC |

| Output: | 4 – 20 mA | |

| Features | Description |

| Protection tube in contact with media | W.no. 1.4571 (AISI 316 Ti) |

| Process connection | W.no. 1.4404 (AISI 316 L) |

| Extension length | W.no. 1.4571 (AISI 316 Ti) |

| Union | Nickel plated brass |

| Connection head | Die cast aluminium |