สินค้าทั้งหมด

DANFOSS MEP 2600/2650 Series Pressure Transmitters are robust OEM pressure transmitters featuring an integrated pulse snubber that effectively protects against cavitation and fluid shock. Their solid design delivers excellent vibration resistance and exceptional mechanical strength. In addition, the series offers a high level of EMI/EMC immunity, making these electronic pressure devices suitable for a wide range of applications.

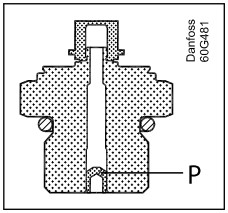

The integrated pulse snubber protects the sensor from cavitation, liquid hammer, and pressure peaks that may occur in fluid systems when flow velocity changes rapidly—such as during fast valve closure, or when pumps start and stop.

These effects can occur on both the inlet and outlet sides of a system, even in low operating-pressure installations. Fluid viscosity only has a minor influence on response time; even at viscosities up to 100 cSt, the response time remains below 4 ms.

Figure 1: Integrated pulse snubber (Pulse-snubber)

| Type | MEP 2600 and MEP 2650 |

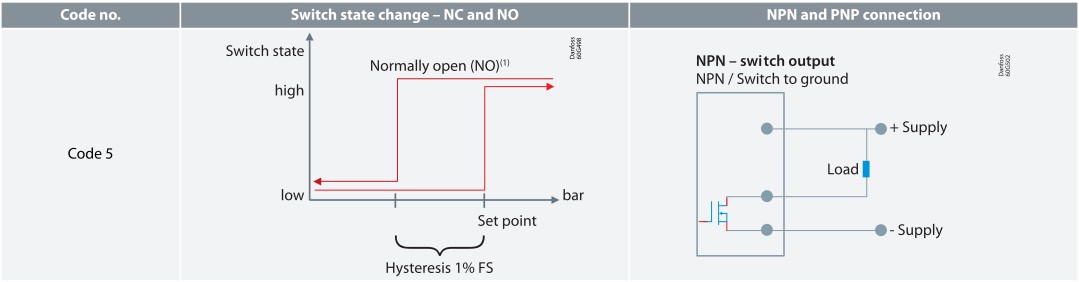

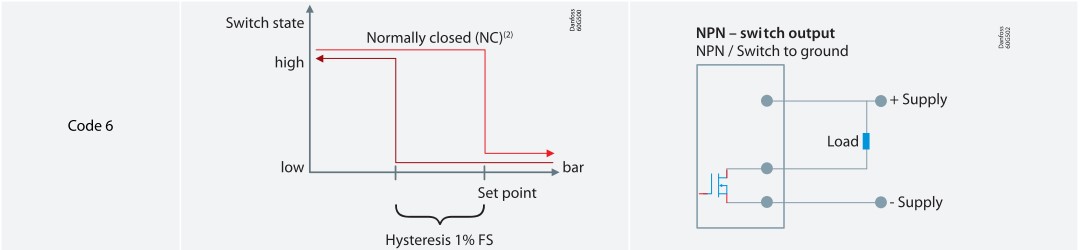

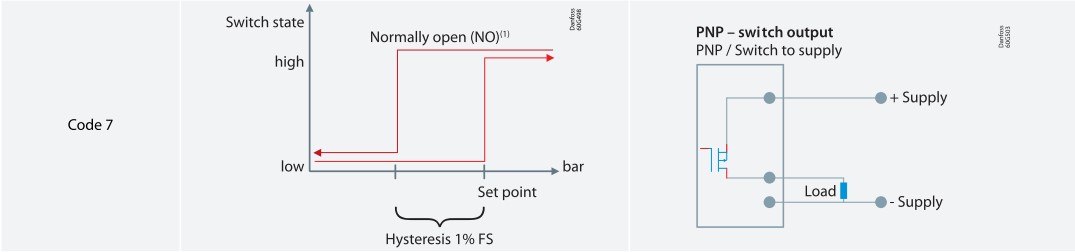

| Switch output (Switch – output) | |

| Switch Hysteresis | 1 – 8% FS |

| Switch Time delay | 8 – 512 mS |

| Accuracy (incl. non-linearity, hysteresis and repeatability) |

2% FS (1 – 5% Hysteresis) 3% FS (6 – 8% Hysteresis) |

| Thermal accuracy | < ± 0.15% FS / 10K |

(1)For detailed information please contact Danfoss.

| Features | Values | |||||||||||||

| Nominal pressure[bar] | 10 | 16 | 25 | 40 | 60 | 100 | 160 | 250 | 400 | 500 | 600 | 1000(2) | 1600(2) | 2200(2) |

| Overload pressure | 30 | 48 | 80 | 80 | 140 | 200 | 320 | 500 | 800 | 1400 | 1400 | 2000 | 2500 | 3000 |

| Burst pressure | 400 | 640 | 800 | 800 | 1400 | 2000 | 1600 | 2500 | 4000 | >4000 | >4000 | >4000 | >4000 | >4000 |

(2)Only available wih M12 × 11.5 P high pressure port, type FC06. Please contact Danfoss.

| Features | Values | ||||||||||

| Nominal pressure [bar] | 10 | 16 | 25 | 40 | 60 | 100 | 160 | 250 | 400 | 500 | 600 |

| Overload pressure | 30 | 48 | 120 | 120 | 210 | 300 | 480 | 750 | 1200 | 2100 | 2100 |

| Burst pressure | 400 | 640 | 800 | 800 | 1400 | 2000 | 1600 | 2500 | 4000 | >4000 | >4000 |

| Type | MEP 2600 and MEP 2650 |

| Switch output (Switch – output) | |

| Max. load(3) | 500 mA |

| Electrical connector types | See Electrical connections |

| Max. inrush load | 600 mA |

| Supply voltage | 8 – 32 V |

| Over/reverse voltage | ± 33 V |

(3)For inductive load limits, please contact Danfoss.

| Nom. output signal (Short-circuit protected) | NPN and PNP | NPN | |

| 0 – 5, 1 – 5, 1 – 6 V | 0 – 10 V | 10 – 90% ratiometric | |

| Supply voltage [UB], polarity protected | 8 – 32 V | 12 – 32 V | – |

| Supply – current consumption | 4.5 mA | 4.5 mA | 4.5 mA |

| Output inpedance | ≤ 90 Ω | ≤ 90 Ω | ≤ 90 Ω |

| Load [RL] (connected to 0 V) | RL ≥ 10 kΩ | RL ≥ 10 kΩ | RL ≥ 5 kΩ |

| Load [RL] (connected to + V) | Not possible | Not possible | RL ≥ 5 kΩ |

| Features | Values | |

| Media temperature range | – 40 – 125 °C | |

| Ambient temperature range | – 40 – 125 °C | |

| Compensated temperature range | – 40 – 125 °C | |

| Transport temperature range | -55 – 150 °C | |

| EMC – Emission | EN 61326-2-3: 2013 | |

| EMC Directive | 2014/30/EU | |

| EMC – Immunity RF field | 100 V/m, 26 Mhz – 1 GHz | EN 61326-2-3 Cable < 30 m |

| 3 V/m, 1.4 GHz – 2.7 GHz | ||

| Electrical performance comply with | ISO 7637 pulse 1 – 4 V (MEP 26XX) | |

| ISO 7637-2 / ISO 16750 (MEP 22XX) (pulse 5b <45 V) | ||

| Vibration stability | 20 g, 10 – 2000 Hz, sinus | EN 60068-2-6 |

| Shock resistance | 100 g | EN 60068-2-27 |

| Materials | |

| Wetted parts | 17 – 4 PH |

| Enclosure | AISI 304 or plastic |

| Pressure connection | 17 – 4 PH |

| Electrical connection | See Electrical connections |

Dimensions / Combinations with recommended torque

HEX is 22 mm across flats.